Macro Pad

In preparation for putting together a full keyboard, I decided to turn a switch tester I purchased off of Amazon into a 3x3 macro pad! Here’re some notes and photos from my project. This post is about two weeks late, but better late than never…

I chose to use the QMK firmware library to program this so I was going to work with the standard matrix setup used on most keyboards. Link: Quantum Mechanical Keyboard Firmware

Here’s the switch tester I originally purchased: Akwox 9-key Cherry MX Switch Tester

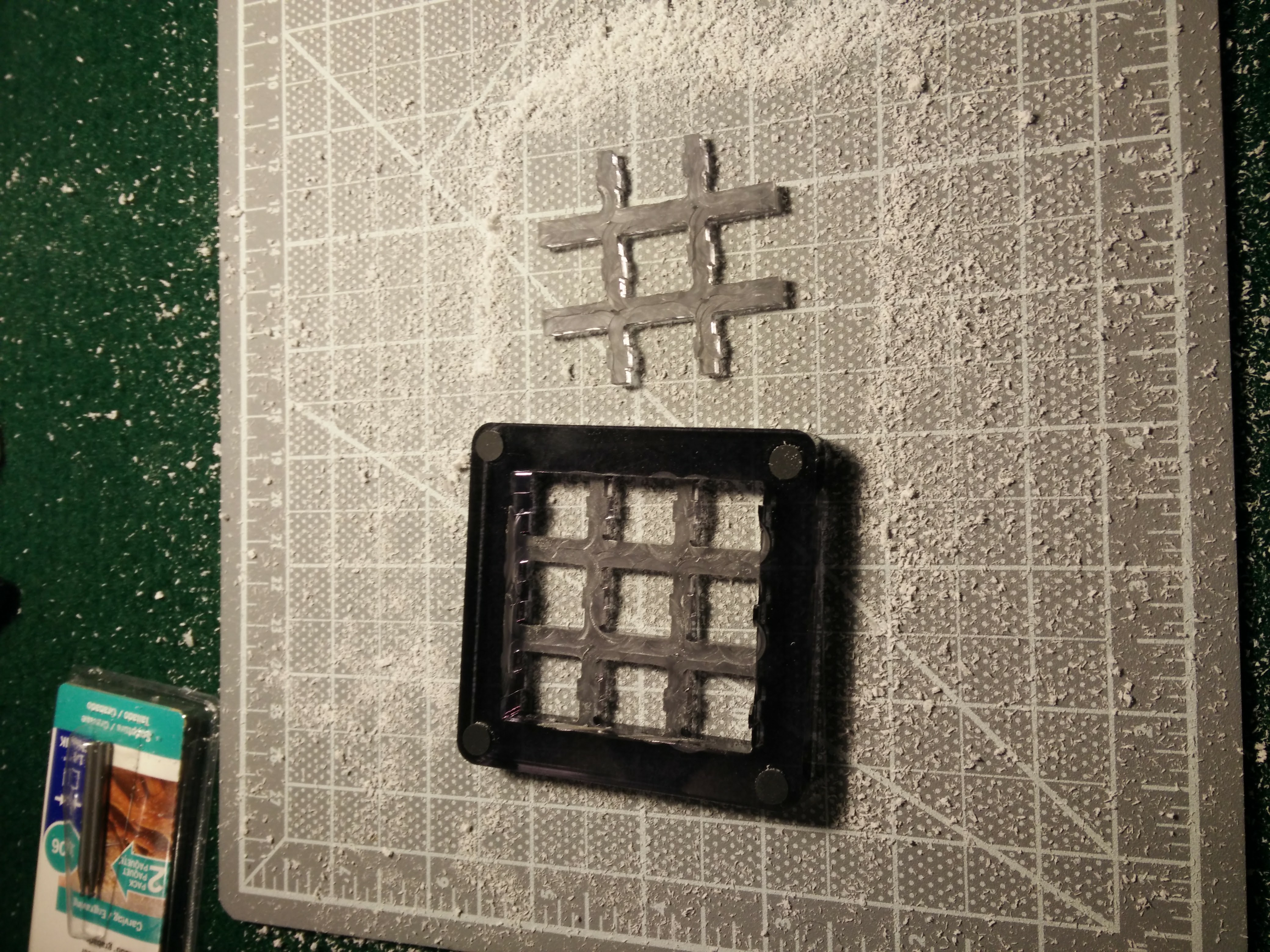

So, the first step was cutting some acrylic out of the bottom of the case so that I could wire the switches together. It turns out that acrylic fumes are nasty, and acrylic dust tears up your lungs, so ventilation and a face mask were required. After running to the store for a new cutting bit I was able to get the cuts made to fit my wiring.

You can see in tihs shot that I also cut small notches for the switches to click into as the original case was missing this.

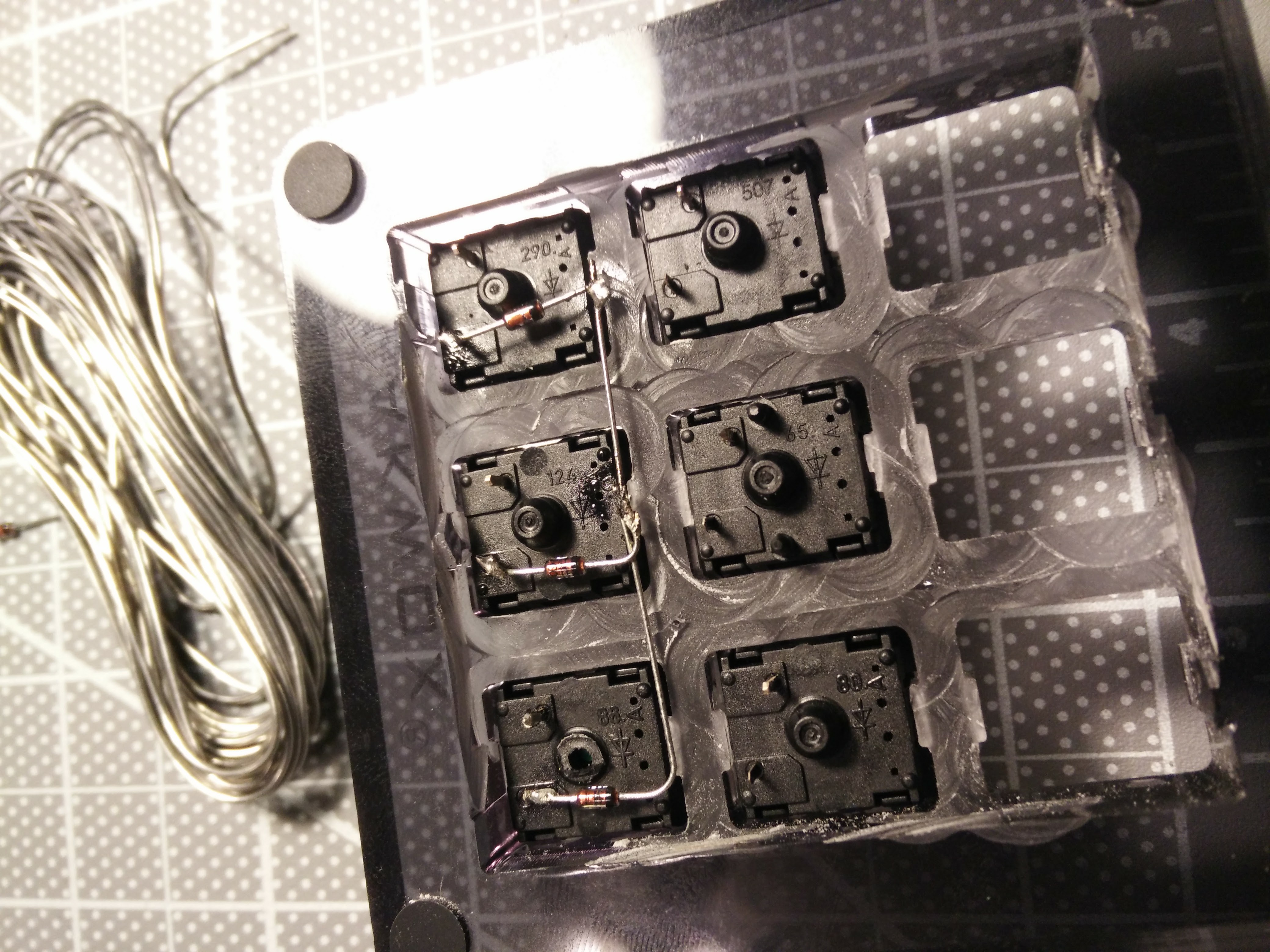

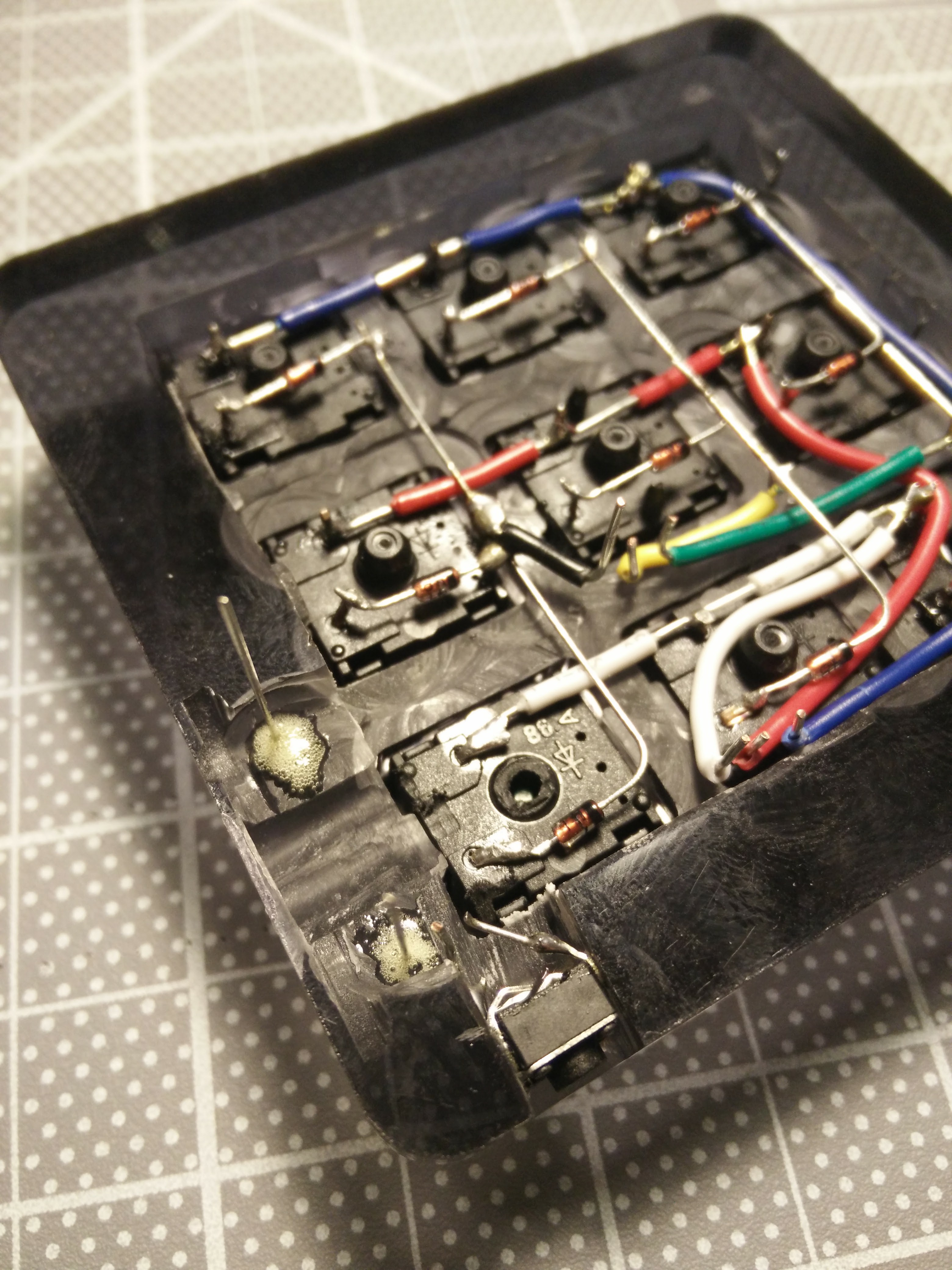

Originally, I wasn’t sure how I would end up mounting the Pro Micro, but I figured I could add height with some M3 spacers if I needed it and I’d just deal with my first build looking like a keyboard on stilts. As it turns out, that wasn’t necessary. I test-fitted and found that I could almost fit the Pro Micro flush with the bottom of the acrylic by bending the pins on two of the switches to give me some space. I also ended up clipping the bottom of one of the switches that would sit on top of the controller. This turned out to cause an issue where the plunger would overpenetrate and get stuck rather than bottoming out (though in reality it would be bottoming out - straight into the ATMega32u4). Here I’ve started (poorly) soldering diodes but you can see that clipped switch and that one of the pins has been bent (the other was bent later in the process).

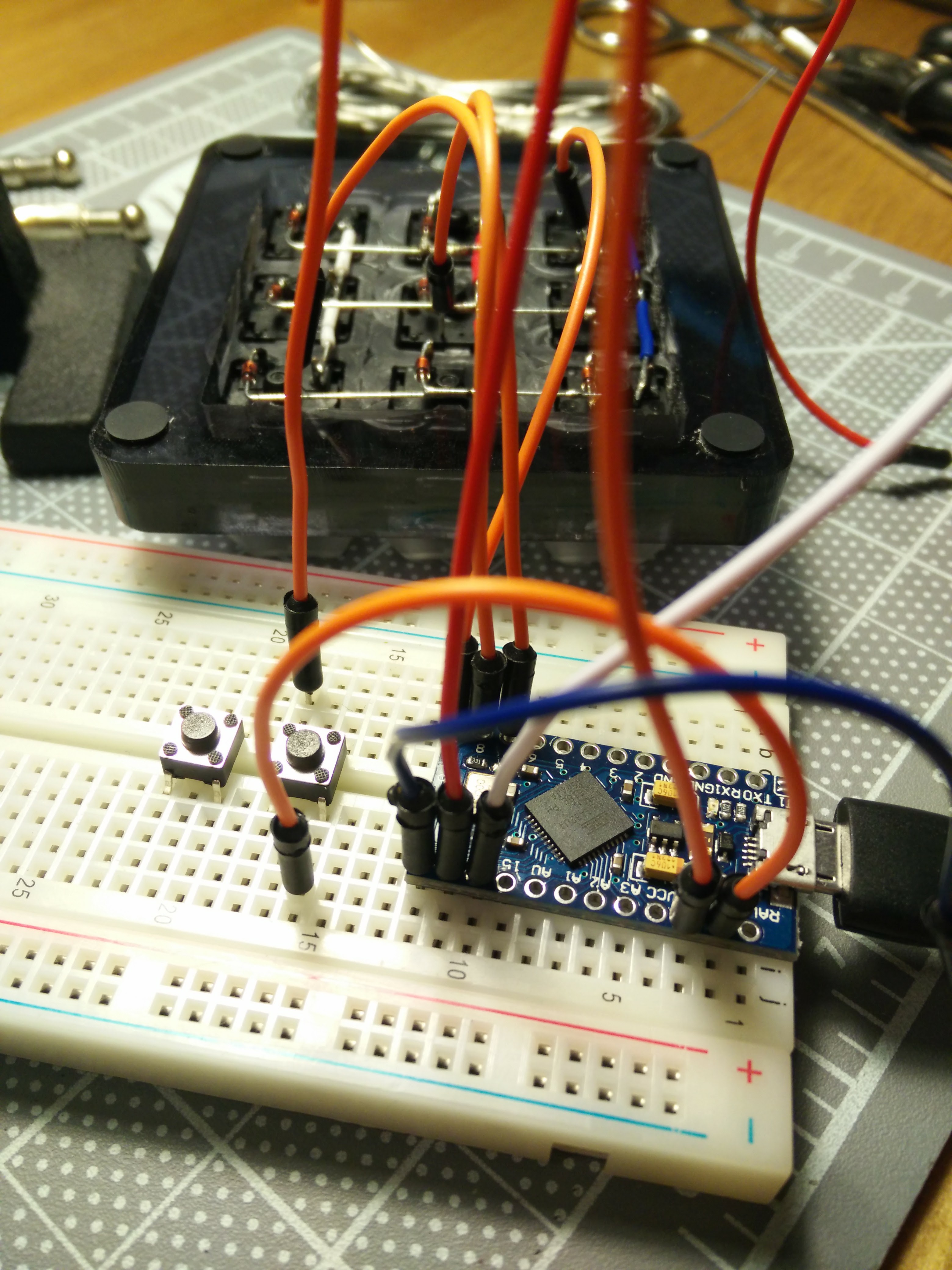

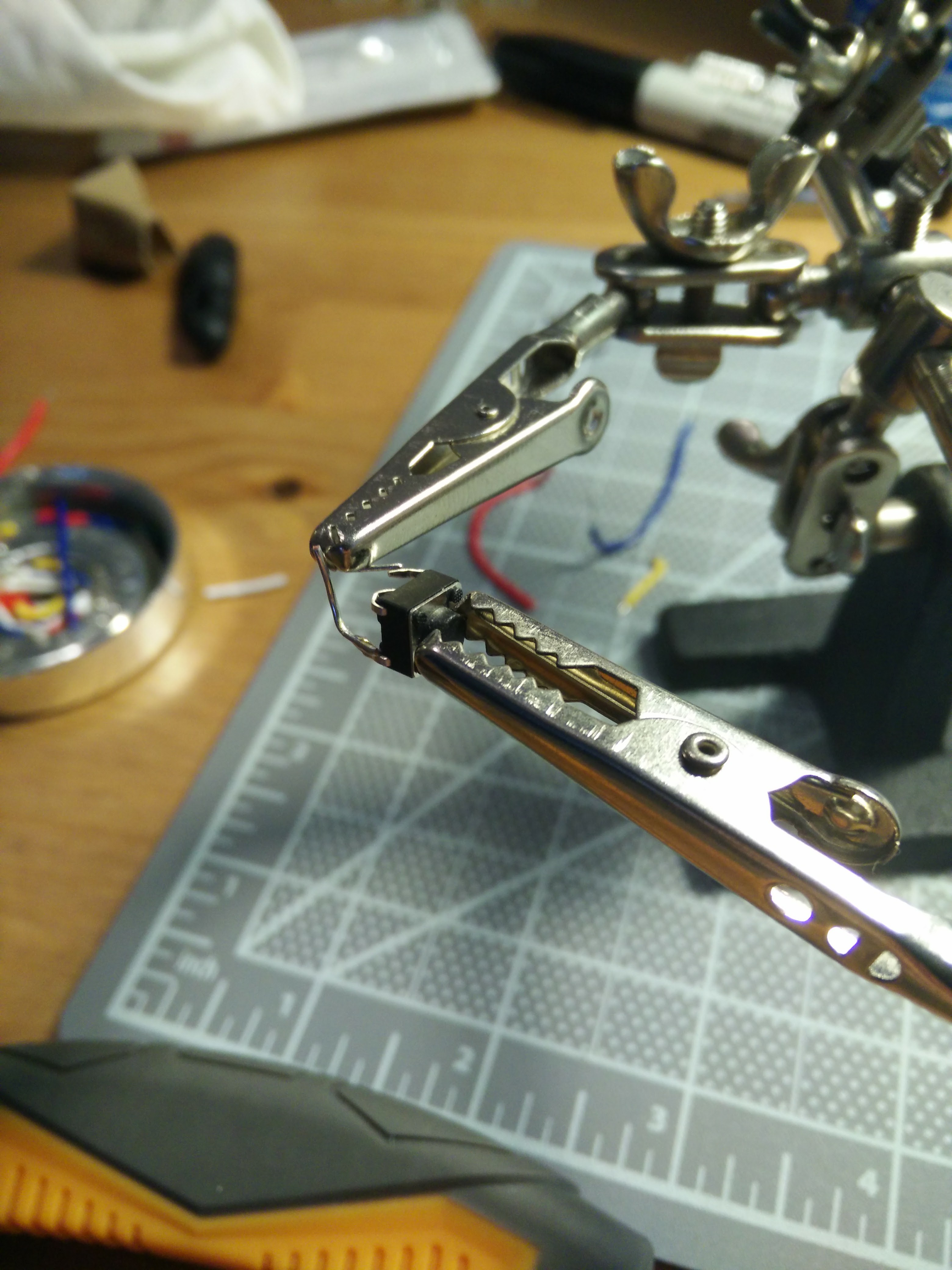

Soldering went pretty quickly and my joints improved as I got the hang of it (and after another run to Home Depot for a couple alligator clips to help hold things in place). As this was my first build I wanted to make sure I had gotten everything right before atually wiring in the Pro Micro, so I decided to do some testing. Turns out that getting this sucker to work with those patch wires is miserable. I ended up wedging a keycap into the middle to apply pressure on all of the pins to ensure stable connections…

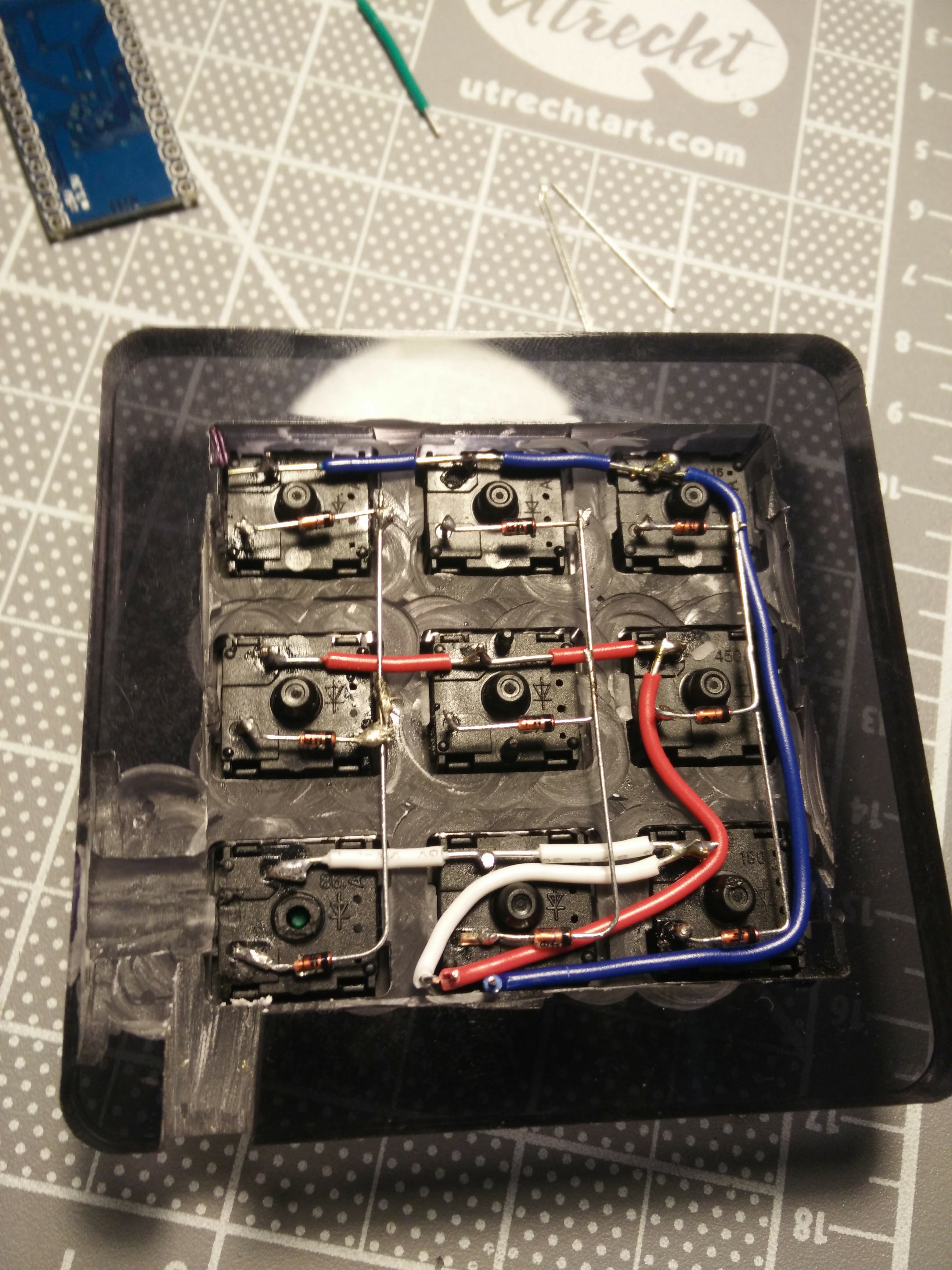

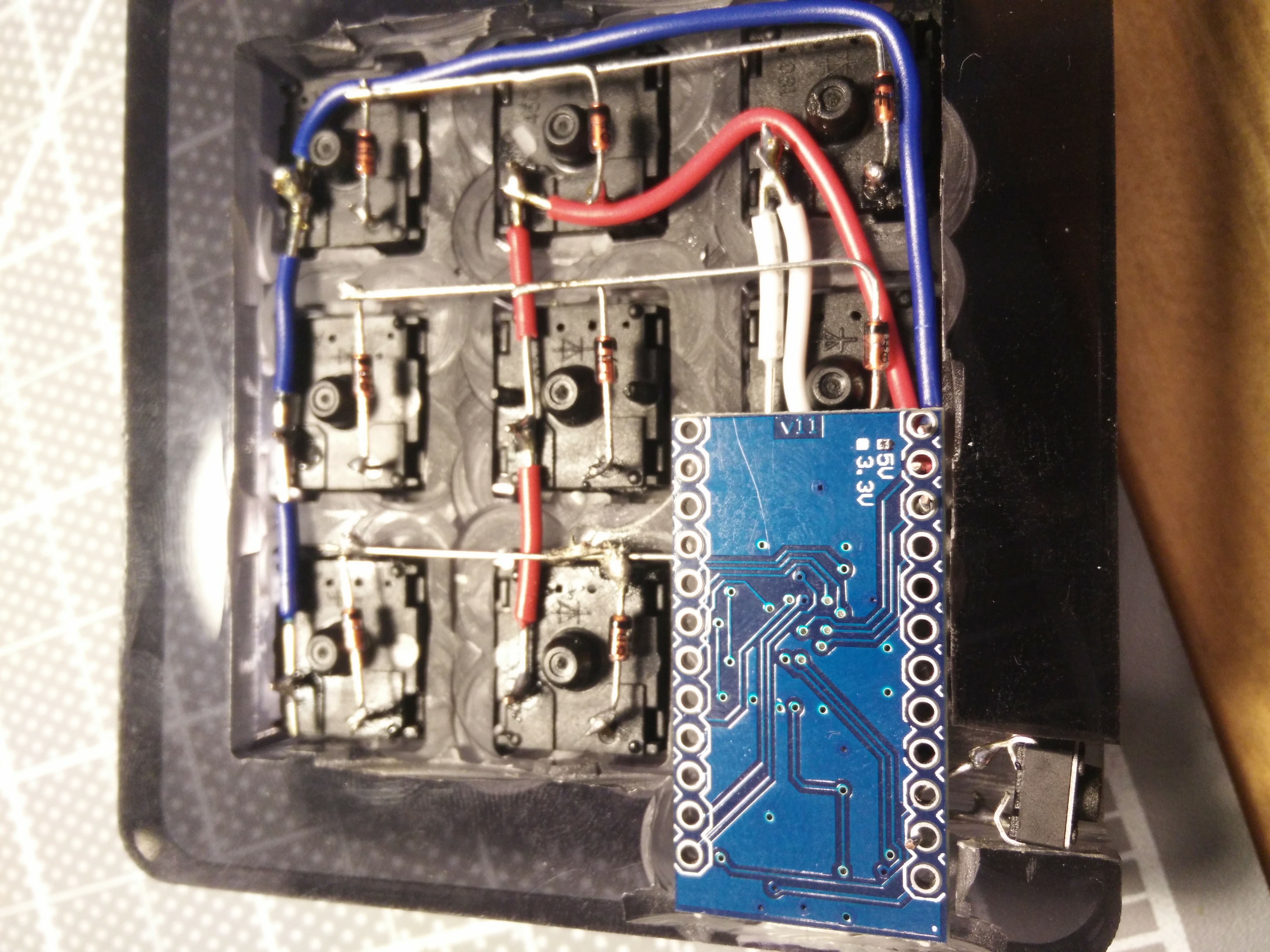

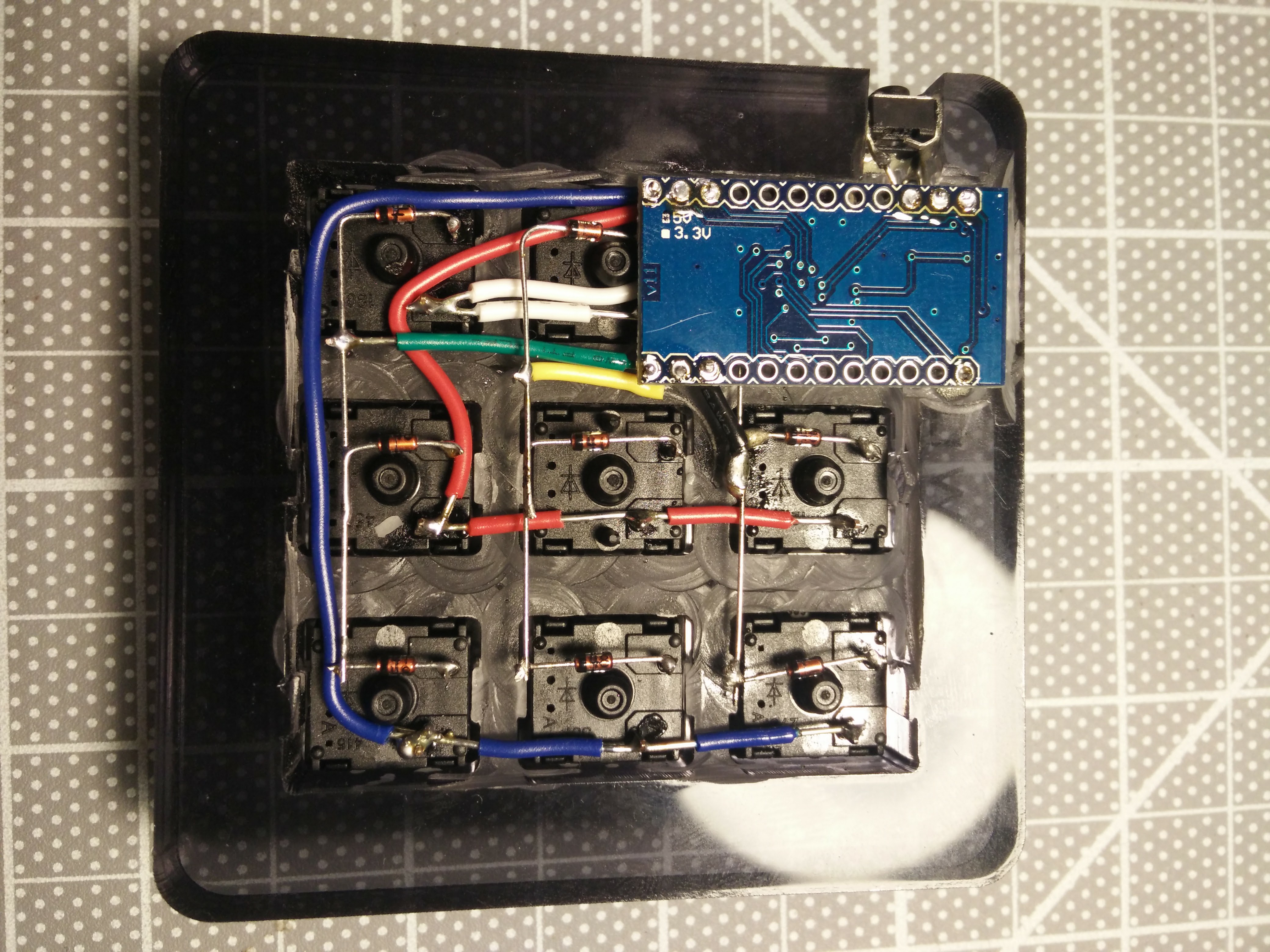

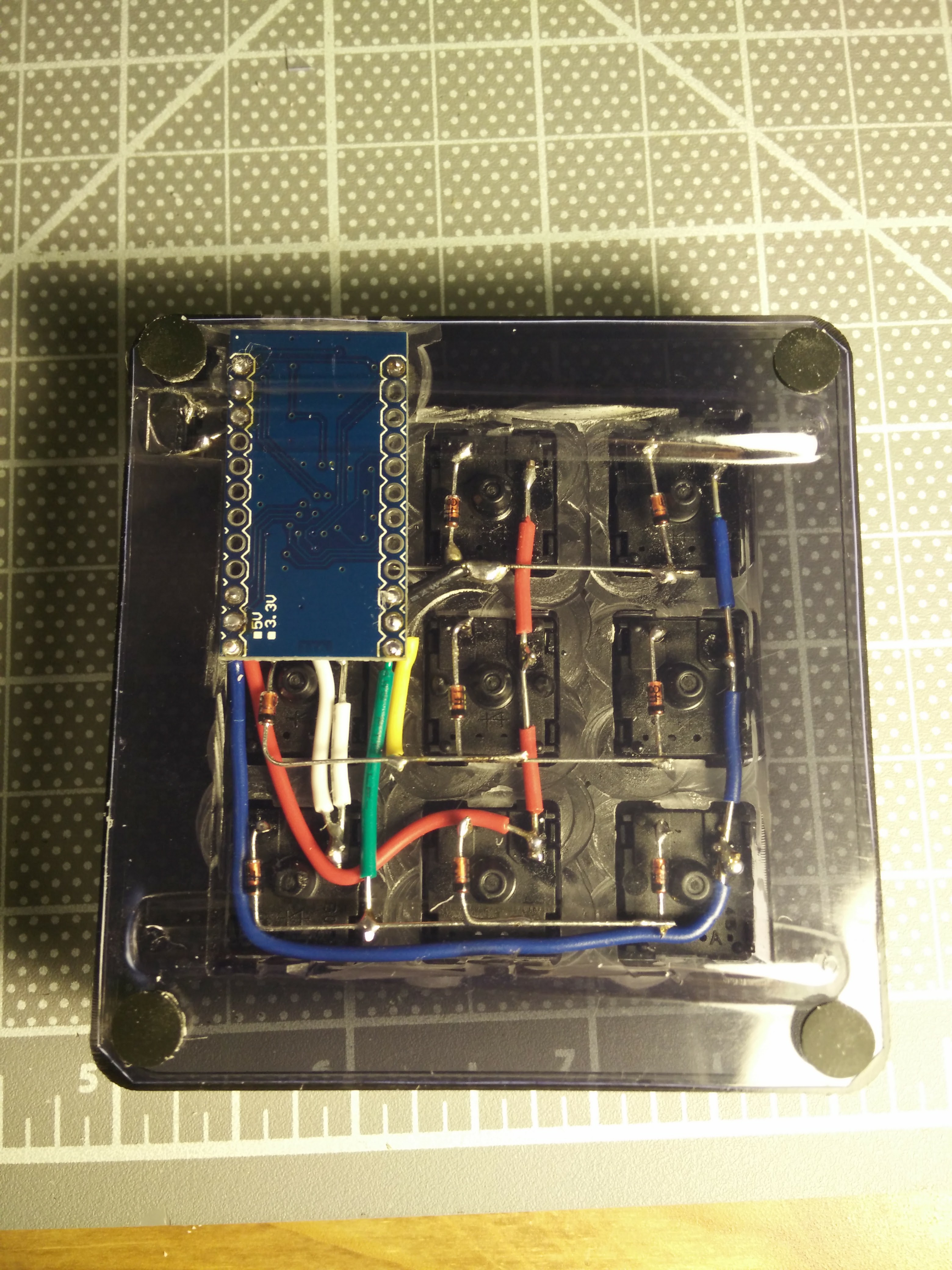

Here’s a nice photo of the finished wiring. Notes:

- most of the solder joints are awful, I know…

- the columns have these color-coded wires snaking through the case to where the Pro Micro will be mounted

- it’s sort of hard to tell the profile from this angle, but the cutout on the right is setup so that only the USB micro port is exposed to the side of the case

- the second cutout (facing bottom of the photo) was made to mount a reset switch

- cutouts were made before the extra wires were added to the columns

Soldering some extentions onto the reset switch so that it could be mounted to the case prior to soldering the Pro Micro.

Here you can see a test-fitting of the controller with all the pins matching up.

At this point I decided I needed to figure out how to actually attach the Pro Micro to my case. What I ended up doing is drilling some holes in the case and using Gorilla Glue to set a few pins (extra lengths clipped from the diodes) into those holes. The idea was that with those secure I could then solder these to two unused pins on the Pro Micro and count on these solder joints and the glue to keep the thing in place. This next photo shows the wiring from the rows to the controller in place and some alligator clips holding the diode clippings in place while the glue sets.

With the stabilising pins set I had only to secure the reset button with some more Gorilla Glue. You can see (barely) the two extensions I soldered onto the switch sticking up to the right of the closer dummy pin.

And here it is soldered and clipped! Not sure if you can really tell in this photo but my solder joins got a lot better by this point and they were all pretty clean on the board (at least compared to a few of the earlier ones).

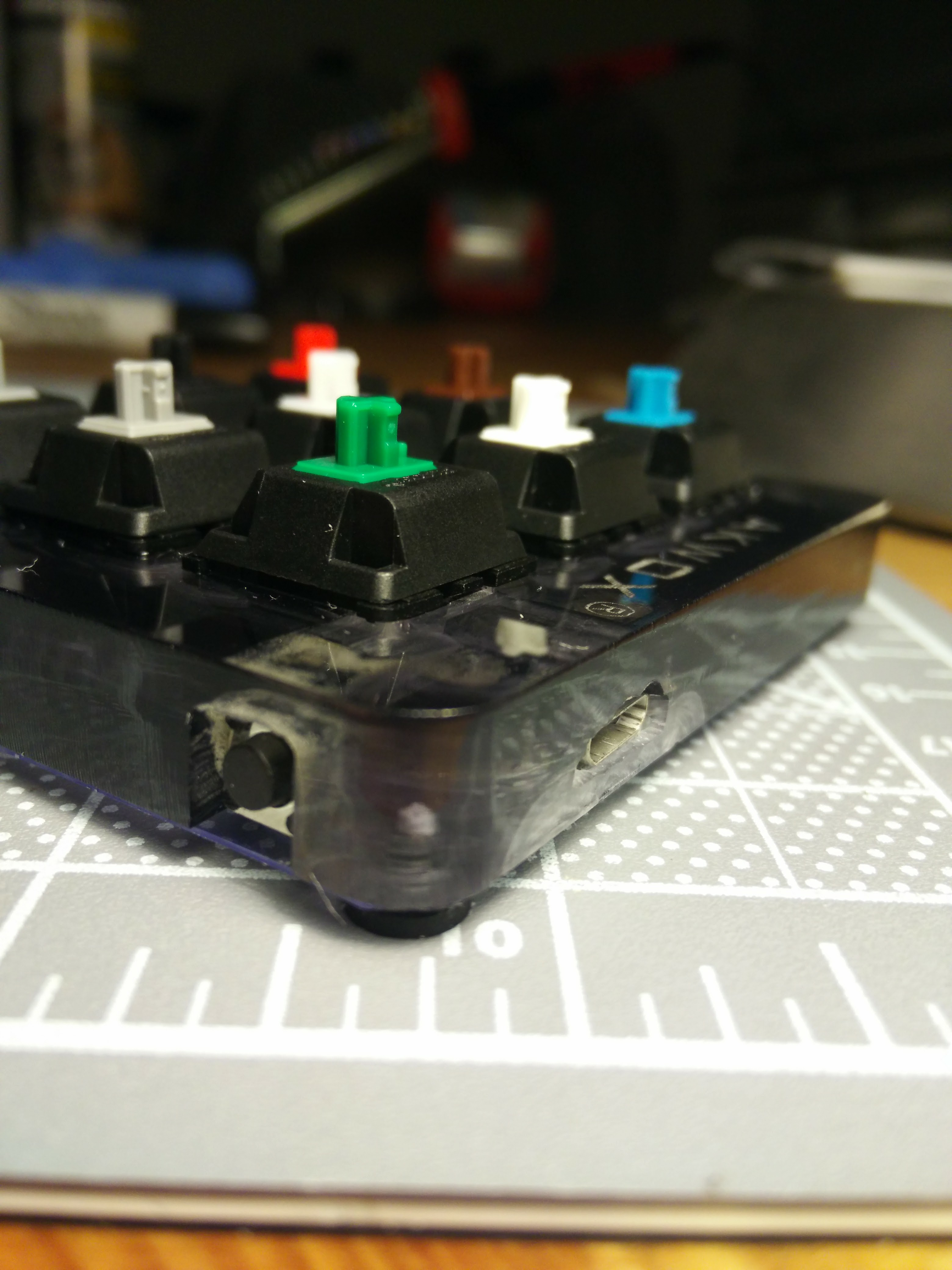

Here’s the view from the sides of the case. You can see that my drilling for the Micro USB slot was a bit sloppy and that I underestimated the expansion properties of Gorilla Glue when mounting the reset switch.

This shows the bottom after I did something sort of silly. I cut out a square of the right size to cover the back of this case from some of that annoying plastic blister packaging. For some reason this one had a couple of rounded protrusions on it which ended up working as feet once those rubber things fell off the screw heads. I think it works pretty well for an ersatz dust cover AND it lets me show off the internals of my first project.

The plan was to gain some basic familiarity with soldering and with QMK and I’ve achieved both of those goals. From this point, It’s likely that I’ll make one of these for at least one of my family members that uses a LOT of keyboard shortcuts all day (working in Excel and Access will do that to you…) and see what I can do with this little pad. That’s all folks! I hope this was entertaining or helpful to someone else - it certainly was for me!